WHAT YOU GET

An AS9120 & ISO 9001-2008 Certified SDB providing services to the following standards:

MIL-PRF-38534 & MIL-PRF-38535

For solder coverage

GEIA-STD-0006

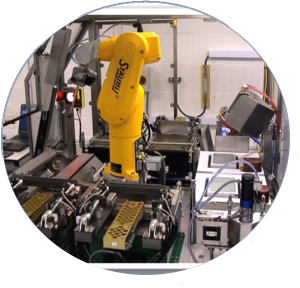

Requirements for robotic solder finish on Electronic Components

IPC/ANSI J-STD-001

For Trim and Forming and Hot Solder Dip

IPC/ANSI J-STD-002

For Solderability Test

ANSI STANDARD EIA-481

For Tape & Reeling

BILL OF MATERIAL ANALYSIS

SMART takes Obsolescence Management to a new level by incorporating all of the key ingredients required for program supportability. Complete life cycle management and software processes meet your specific program requirements.

Simplifying DISTRIBUTION

Performance Quality Support

We have always provided semiconductor products and solutions for the customer who understands quality and value based on solutions and services we can provide. With that in mind and in conjunction with our strategic business partners, we have now developed a Value Added Services program to address many of your component modification and testing needs.

Click here to download PDF version of Value Added Services

Flexible solutions for your business needs

| Solder Exchange / Solder Dip | ||

|

||

| BGA Modifications | ||

| An established process for bringing back BGA components to their original specification | ||

| Trim and Form | ||

| Trim and Form straight leads for surface mount or through-hole components | ||

| Component Modification | ||

| Leaded Components Realigned (Variety of Packages); Solderability Testing; Particles Impact Noise Detection (PIND); Fine and Gross Leak Testing; Lead Integrity Testing; Tensile Testing(Bond/Lead Pull); Tape and Reel |

||

Semiconductor Services

| All Tech also offers Upscreened Components |

| “Up screening” components to meet your requirement. |

| We will process lot sizes from small to high production volumes. |